leading heater machines factory in China. Welcome to http://heater-machines.com/ for heating machinery.

2024年4月16日星期二

Semi Auto Tapering Machine GT LJ202 for water heater measure temperature tube production

2024年3月27日星期三

Automatic Threading Machine for terminal pin rod produciton

GT-YBCY201 Automatic Threading Machine use to make thread on the terminal pin rod.

Function:

*** make thread on terminal pin;

Main features:

*** semi auto machine, easy operation;

*** Length of thread can adjust;

*** Depth of thread can adjust;

Application:

Suitable to make thread on metal terminal pin for heaters.

Information need for order GT-YBCY201 Automatic Threading Machine:

*** diameter of pin and thread to make;

*** Length of thread to make;

*** Length of pin;

*** power supply: such as 3 phase 380V, single phase 220V, 50HZ.

2024年1月22日星期一

What is Cartridge Heater?

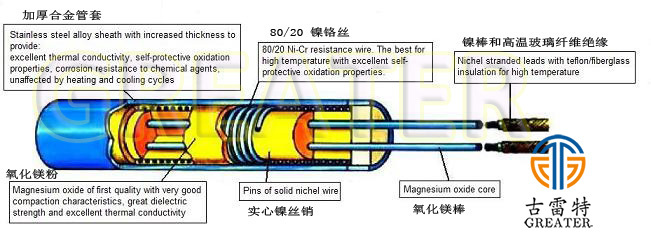

A cartridge heater is a type of electrical heating element that is typically used in industrial applications. It is also named as single end heater, mold heater.

It consists of a cylindrical metal tube, usually made of stainless steel, with a heating coil or resistance wire inside. The coil is insulated with a ceramic or magnesium oxide material to provide electrical insulation and thermal conductivity. Some cartridge heater with a long extermal terminal pin or wire cable.

It consists of a cylindrical metal tube, usually made of stainless steel, with a heating coil or resistance wire inside. The coil is insulated with a ceramic or magnesium oxide material to provide electrical insulation and thermal conductivity. Some cartridge heater with a long extermal terminal pin or wire cable.

Cartridge single end heater mainly in one shape like a cartridge heater, and there are also some in L shape or some special shape.

Cartridge heaters are designed to be inserted into a hole or cavity in a solid material, such as metal or plastic, to provide localized heating. They are commonly used in applications such as plastic injection molding, packaging machinery, food processing equipment, and heating of liquids or gases.

Cartridge heaters are known for their high heating efficiency, fast response time, and precise temperature control. They can be customized in terms of wattage, voltage, length, diameter, and other specifications to suit specific heating requirements. Machines for make cartridge heaters are some easy heater equipments than other heating element machines.

Cartridge heaters are known for their high heating efficiency, fast response time, and precise temperature control. They can be customized in terms of wattage, voltage, length, diameter, and other specifications to suit specific heating requirements. Machines for make cartridge heaters are some easy heater equipments than other heating element machines.

2024年1月8日星期一

What machines need to make tubular heaters?

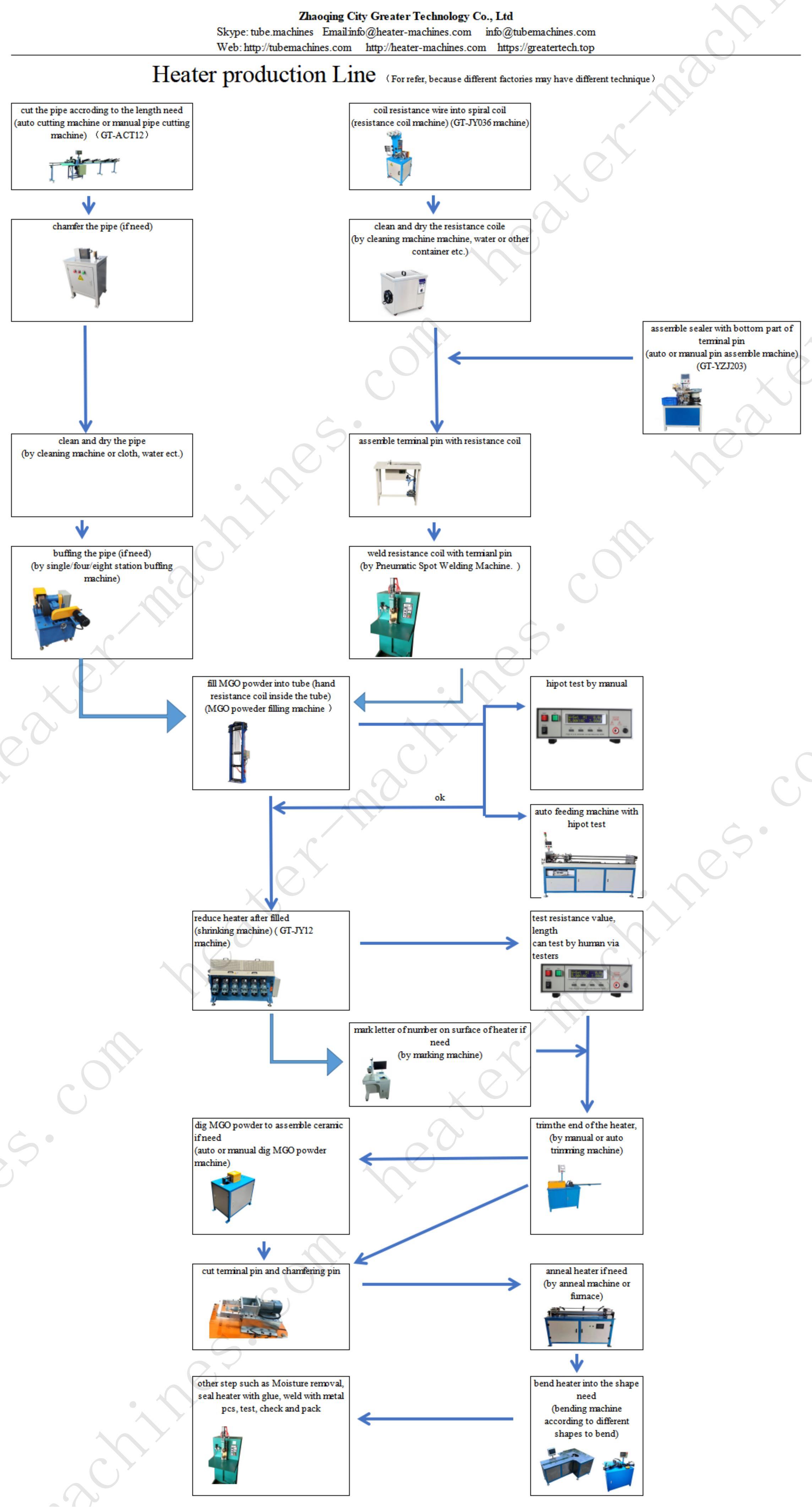

To manufacture tubular heaters,below are recommend machines:

1. Tube cutting machine: cut the tube according to the length need.

If you buy correct length directly from tube factory, can ignore this machine.

However, most heater factories will cut the length by themselves, to make more different style heaters.

2. Tube chamfering machine: After cut the tube, there maybe some burrs in the end of the tube. Use a tube chamfering machine to chamfer before fill MGO powder is recommend.

3. Winding machine: to coil resisatance wire into spiral coil, which will put inside the tube during fill MGO powder.

4. Cleaning machine: to clean resistance wire coil after wind. Some factories may use other container to clean.

5. Plug sealer assemble machine: this machine mainly to assemble bottom terminal pin with plug sealer.

6. Resistance coil with terminal pin assemble machine: this step can assemble by hand, or use a simple machine to assemble pin with resitance coil, which will be quicker and more easy than by hand.

7. Spot Welding Machine: Welding machine use to weld terminal pin with resisatnce coil, to avoid resisatnce coil being away with terminal pin during filling MGO powder;

8. For shorte heater, such as heater within 1 meter, can use an automatic tube arrange machine, to put the tube one by one on the rack, and take them one time to install on filling machine. One tube arrange machine usually can match with 2-3 filling machine.

9. MGO filling machine: fillg MGO powder into the tube, and put resistance coil with pin+ plug;

10. After fill MGO powder, the top of heater need to cover plug for next step. If heaters within 1 meter, can use automatic upper plug assembling machine to cover top plug auto. One plug assembling machine usually can match with 2 filling machine. If heaters more than 1 meter, cover plug by worker maybe easier. One reason is to carry about 24 pcs filled heater more than 1 meter is too heavy.

11. Auto feeding machine + hi-pot tester machine: For long tubular heaters, such as heaters more than 2 meters, to feed by worker is also a good idea.

Strong recommend do hi-pot test before reduce heaters. Because if heaters is not good, can take out some material and re-use. If after reduce, and heater not good, the un-quality heater can not use anymore.

12. Shrinking Machine: to reduce heater into smaller diameter, to increase density.

13. Trimming machine: trim the end of heater. Depend on length of heater and budget, can choose auto or semi-auto trimming machine.

14. Dig powder machine: if need to install ceramc on both end of heater, need to dig some MGO powder. Depend on length of heater and budget, can choose auto or semi-auto dig powder machine.

15. Terminal pin cut machine: One end of terminal pin with neck, usually need to cut the terminal pin. Depend on length of heater and budget, can choose auto or semi-auto terminal pin cut machine.

16. Chamfering pin machine: After cut terminal pin, the edge of pin maybe sharp, most people will chamfering the end of terminal pin. This will install nut more easy, and heater in better quality.

17. Anneal machine or furnace: If need to bend heaters, most heater will need to anneal before bending.

18. Bending machine: to bend different shapes, diameter, usually require different bending machines.

19. Marking machine: Many heater facotories will mark their logo, KW, V, date on the heater, so you may require a laser marking machine.

Above machines are some popular tubular heaters machines and steps in Greater heater machines.

To make tubular heaters, different supplier may have their technique,

so some machines or steps maybe a little different. Do you have your idea how to make tubular heaters?

tubular heater machines|machines to make tubular heaters|double end heater equipment|electric heater machinery|tubular heater produciton

tubular heater equipment, machines to make tubular heaters, double end heater machines, electric heater machine, tubular heater produciton,

What machines need to make tubular heaters? How to make tubular heating elements? How many machines need for manufacture tubular heaters? Zhaoqing Greater share popular tubular heaters machines to make heating elements.